THE CHOICE OF RAW MATERIALS

An accurate selection of raw materials is the first step for the success of the projects.

IAMET offers a wide range of metal alloys and treated precious materials.

BASIC MATERIALS

The most used materials are: copper alloys, aluminium alloys, steel in the most varied and complex compositions.

GALVANIC BATHS AND SURFACE COVERS

IAMET treats precious materials and components based on gold, silver, palladium and ruthenium.

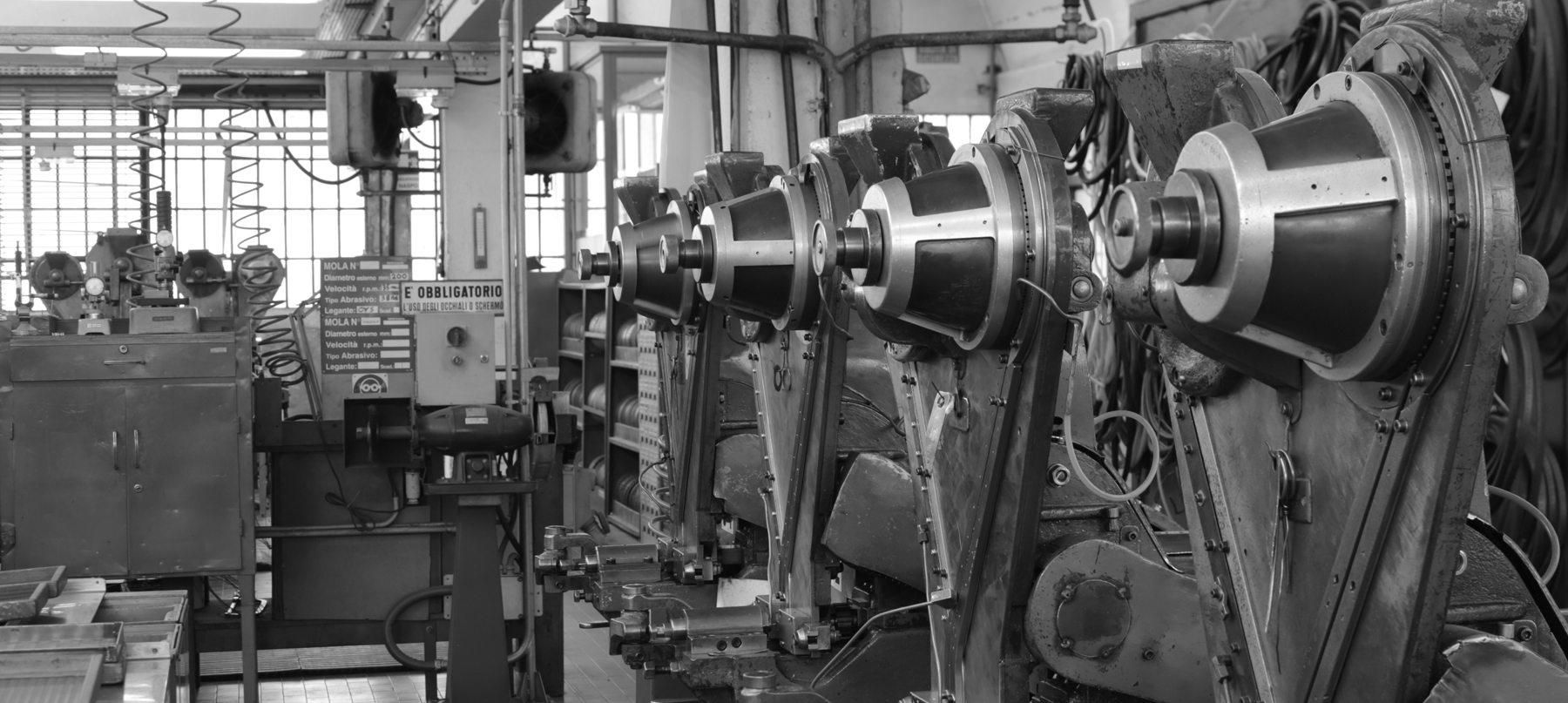

INTEGRATED PRODUCTION CYCLE

The integrated production cycle is totally MADE IN ITALY and verticalized within the company: from the choice of raw materials to packaging.

In this way IAMET can guarantee the quality and uniformity of the single detail.

Each product, since the prototype phase, is subject to rigorous testing protocols.

WORKINGS:

- Cold molding from tape

- Zamak die-casting molding

- Turning with movable head

- Mechanical machining on CNC

- Marking / Coining

- Grind

- Polishing

- Welding

- Painting

- Tumbling / ceramic coating

- Galvanization

- Sandblasting

- Brushing

- Assembly

- Packaging

QUALITY RESEARCH

All processes are submitted to intermediate and final control, with statistical methods or 100% with camera control.

IAMET is already in the future, thanks to a continuous investment in research and updating, which allows it to meet the requirements of Industry 4.0